Introduction

I can do most things with my laptop, why can’t I make it

cook? I’ve attached sensors, motors, NMR, cameras, etc. why not a heater and a

thermometer?

Sous Vide, or immersion cooking produces great tasting food.

It is also an interesting representative problem of closed loop temperature

control. With numerous people trying to provide an open source or DIY solution

for Sous Vide cooking, I figured I’d add to that body of work in my own way.

I’d write a software simulation of an immersion cooker to help people develop

better hardware. I don’t know what the time constants in the simulation might

be, but you can set them, and learn PID control. I also might hook up a relay,

a heater, and a thermo couple and actually do this, but mostly I figured I’d

help others study basic PID control.

Background

PID control loops (Proportional, Integral, Derivative) are a

basic form of closed loop control, meaning the error is fed back into the

control loop and used to change how control is performed as opposed to open

loop.

In a PID loop, an error is calculated, and then three

different terms are computed and summed to form a correction. The incoming

error term may have known properties based on how the measurement was made or

changes to the goal value, so sometimes pre-filtering is performed (FIR/IIR).

The integral sometimes isn’t truly just adding up the errors but sometimes

decays so it has a limited memory of past errors. The derivative term may be

subtracting two noisy errors that are similar producing a large value that is

mostly noise so sometimes the derivative value is filtered (FIR /IIR, outlier

rejection, boxcar, etc.).

Finally each of these terms may have a dead band, and the

sum may too. A dead band means don’t adjust unless over +X threshold amount, or

under –Y threshold amount. Further the control applied may also be filtered to

remove control changes that would cause a harmonic pattern, such as

oscillation.

So with this in mind, a generic PID may have a large set of

features (pre/post filters), dead bands, and pre /post conditioning filters,

and a variety of integration like effects.

PID Tuning

In general, a PID filter can be thought of as a corrective

loop, where you move closer to the goal proportional to the error perceived. In

many cases a proportional gain is what’s needed. For example for servo motion

where there is a large motor and a tiny weight, driving to position requires

only a P term. If there is consistent pressure (weight) or loss (heat loss)

proportional control may not be enough. The integral term adds up tiny errors,

and corrects better than proportional when the error is small. The integral

term may accelerate too much resulting in over correction and even oscillation,

so the derivative term is then used like a break.

There are several tuning techniques, the author prefers

starting with Ziegler-Nichols. I set the proportional gain till it over

controls resulting in oscillations I can measure. When the system is mostly

linear, the oscillations will have fixed period. This proportional gain is the

“ultimate” gain or Ku, and the period is Pu. From there:

P only: P

= 0.5*Ku

PI only: P

= 0.45*Ku, I = 0.54*Ku / Pu.

PID: P

= 0.6*Ku, I= 1.2*Ku/Pu, D = 0.075*Ku*Pu

In most cases, this is close to good enough. In the case of

a Sous Vide, overshoot (going too hot while attaining a temperature) is bad,

and consistent undershoot is bad. It can take a known time to reach stability

before we put the food in is ok. For this reason, backing off on I and D terms,

and using a decaying integral are likely good ideas.

There are many systems to compute “ideal” coefficients but

they don’t arrive at the same answer, go figure. Ideal is based on your

particular requirements, and simulation helps a lot. Integrating with the real

system then tells you how much more work to do, it usually isn’t a check the

box test unless you’re lucky or the control system was simulated perfectly, or

it is relatively linear and or simple. Most problems I’ve used PID on started

simple, then weight was cut, materials changed, etc. and at some point

simulation became just a starting point. At some point PID stops working and a

lookup table based on measurements for coefficients to interpolate from is

required. That is the essence of an autopilot because that kind of algorithm

can model non-linear processes that appear linear or quadratic over short

numerical regions (perhaps a different article). My point is, PID usually can

solve the problem if the problem is reasonable but there are other solutions

that sometimes work better.

If your problem seems too hard to solve because small

changes in gains cause the system to behave strangely then likely there is a

non-linear response to the correction and PID might not be the choice to use.

For Sous Vide cooking, temperature isn’t linear in time

(exponential) but it is a smooth effect, and over any short region of change if

we treat it as linear, the error term isn’t huge or suddenly change sign. For

those reasons PID will work, perhaps not ideally converging with zero overshoot

but it works very well and is probably the most common way to handle heating

control.

Requirements

The key thing is to bring food up to a target temperature

ideal for that food, and hold it there for a period of time. For example to

cook an egg so only certain proteins coagulate (perfect poached egg), or to

make the perfect steak, or carrots, the food is cooked longer than needed at no

more than the set temperature, and as close to the set temperature as possible.

Above certain temperatures the heat only breaks down flavor and makes the food

tougher for certain foods.

Temperature:

Min, Max. 1000F

to 2200F (roughly 500C to 1000C)

Accuracy

0.250F (threshold) 0.10F

(goal)

Stability Gaussian

1-sigma of accuracy to time constant of heat transfer.

Overshoot Initial

overshoot of water ok if food isn’t present.

Need to know when food started to be at temperature to know

how long to cook it.

Physical Control:

Either proportionally or pulse an AC heater. Pulsing with a

solid state relay is probably cheapest, but the frequency of the pulses need to

be realistic because they affect how well the heating element will accurately

respond and the life of the heating element.

Physics

Model Assumptions

- Heater has a metal outside surface.

- Water is circulated rapidly to avoid significant

gradients

- Inside of container is metal or water is

circulating so container is a uniform effect on the water.

- Container is an insulator.

- Bag is slightly an insulator.

- Air temperature is room temperature, uniform

(enough).

- Anything that is relatively uniform or

circulates faster than the time constant of transfer to it is equivalent to uniform.

- Relative time constants:

Slow -> Container/Air ->

Container/Water -> Medium ->Bag/Food -> Others -> Fast

Math

Math References

http://en.wikipedia.org/wiki/Heat_transfer

http://en.wikipedia.org/wiki/Specific_heat_capacity

http://en.wikipedia.org/wiki/Fourier%27s_Law

http://en.wikipedia.org/wiki/PID_controller

Mathematics of Physics and Modern Engineering, McGraw

hill publishing, 1966, by I.S. Sokolnikoff & R.M. Redheffer, p. 432.

Indroduction to Applied Mathematics,

Wellesly-Cambridge Press, 1986, by Gilbert Strang, p. 461, 536.

Simulation

The model can be describes as a set of heat transfers. Yes,

the specific heat and energy could be modeled with a more classical

thermodynamic model, but in the end the math reduces more or less to time

constants and transfer from one singular thermal body to another.

The heat escape path is: Water->

Container -> Air && Water->Air.

The add path is: Heater->

Water

The measurement path is: Water->

Sensor

We can turn what could be a wacky looking differential

equation into a set of difference equations .

By making the simulation time arbitrarily small, the error

is arbitrarily small, and computers are good at rapid repeated calculations.

For this reason, FEA modeling or differential equations are just not needed

(although a lot of fun, but not in this article). In short we can simulate

multiple simultaneous heat transfers as heat adding or being lost across a

given boundary, rewriting as a difference:

Because the volume of water is varying, assuming a pot or

rice cooker we can adjust the time constant based on the surface area to volume

ratio and simulate those affects. We can also run the adjustment times at a

different rate to the simulation time delta, and set weather control is

proportional or pulsed and compare the results.

Water volume effect:

Code

private void simulateTime(double dt, double percentHeat, ref double water, ref double container, <br /> ref double sensor, ref double food, Parameters p, PID pid, bool usePID)

{

percentHeat = percentHeat < 0 ? 0 : percentHeat > 100 ? 100 : percentHeat;

if (p.Binary) { percentHeat = percentHeat > 25 ? 100 : 0; }

double heaterAdded = percentHeat * p.HeaterWatts * heaterSpecificHeatFactor;

double effectiveWaterContainer = p.TWC * p.WaterRadius * p.WaterDepth /

(p.WaterRadius + 2 * p.WaterDepth);

double effectiveWaterAir = p.TWA * p.WaterDepth;

double heatAddedToWater = (heaterAdded - water) *

(1 – (1/ p.TWH) * System.Math.Exp(-dt / p.TWH));

heatAddedToWater = heatAddedToWater < 0 ? 0 : heatAddedToWater;

double heatLostToSensor = (water - sensor) * (1-System.Math.Exp(-dt / p.TWS))/p.TWS;

double heatToFood = (water - food) * (1 - System.Math.Exp(-dt / p.TWF)) / p.TWF;

double heatLostWaterContainer = (water - container) *

(1 - System.Math.Exp(-dt / effectiveWaterContainer))/effectiveWaterContainer;

double heatLostWaterAir = (water - p.Air) *

(1 - System.Math.Exp(-dt / effectiveWaterAir))/effectiveWaterAir;

double heatLostContainerAir = (container - p.Air) *

(1 - System.Math.Exp(-dt / p.TCA))/p.TCA;

food = food + heatToFood;

water = water + heatAddedToWater - heatLostWaterContainer –

heatLostWaterAir - heatLostToSensor - heatToFood;

sensor = sensor + heatLostToSensor;

container = container + heatLostWaterContainer - heatLostContainerAir;

}

public class PID

{

double m_p = 0, m_i = 0, m_d = 0, m_g = 0, integral = 0, last = 0;

bool first = true;

public PID(double setPoint, double proportional, double integral, double derivative)

{

m_g = setPoint; m_p = proportional;

m_i = integral; m_d = derivative;

}

public double Update(double sensor, double dt)

{

double error = m_g - sensor;

integral = (0.9 * integral) + error;

double derivative = first ? 0 : (sensor - last) / dt;

last = sensor;

first = false;

return (m_p * error) + (m_i * integral) + (m_d * derivative);

}

}

Results

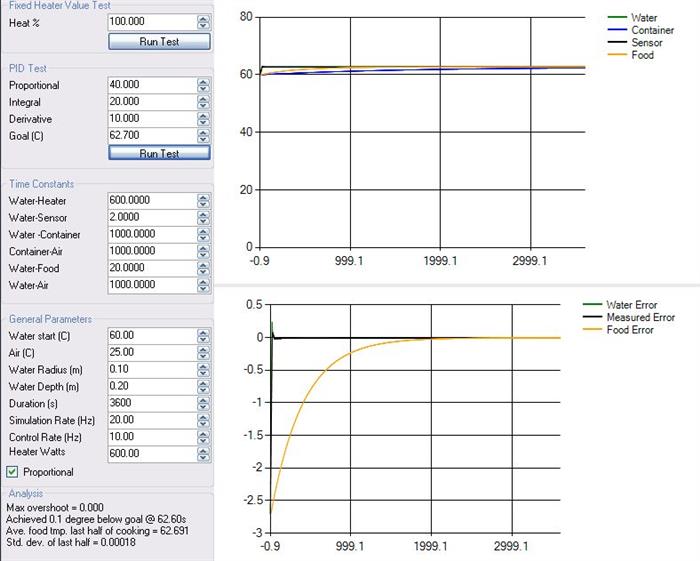

The following time constants in seconds were guessed at to

produce are somewhat realistic simulation:

Water-heater 600

Water-sensor 2

Water-container 1000

Container-air 1000

Water-food 20

Water-air 1000

Sure the time constants are made up. After gathering actual

data, make educated guesses. For anything I’ve worked on (missiles, GPS motion,

thermal control) it was always an estimate, a guess, the reality is even if you

measure the exact value, when you get to production there is enough variation

for the exact value not to matter. Simulation tied to real data ensures that if

the production values vary, the gains provide for robust control anyways. One

of the best ways to do this for real would be to turn the heater on at various

fixed values and measure the steady state water and container temperatures, and

look up the time constant for the thermocouple used, then make the model look

like the curves seen for real, double checking with heat loss vs. heat added. Pure

math often won’t do all the work unless your system is simple and well known

(density of the plastic container, exact CAD model for shape, calibrated heater

wattage, losses in switching on/off, etc.).

It took a proportional gain of over 100 to start to see an

initial overshoot, the inherent decay meant there is no real gain that will

cause an oscillation. Using Ziegler-Nichols, and looking at the overshoot, the

time to decay from an overshoot is in tens of seconds so IF Pu did exist it

would be on the order of 5-20 seconds, and our gain ultimate (Ku) can be large

(10 – 50). This provides ball park initial values to setup and study (Ku = 30,

Pu = 10).

P = 0.6*Ku, I= 1.2*Ku/Pu, D = 0.075*Ku*Pu

P = 18, I = 3.6, D = 22.5

This resulted in the following graph:

The problem is it was 0.2 degrees too cool for the second

half of cook time, clearly we need more integral. Doubling the gains brought

the system closer (62.69).

Note what happened when I used non-proportional pulsed

control:

Because the food provide a sort of temperature buffer, it

takes time to transfer water to food through the bag the food is in, a little

water overshoot is desirable if accuracy is improved. For this reason we can

play with the numbers and improve performance.

If this was more than an intellectual exercise, the next

step would be to randomly generate start water temperatures (which also has the

affect of spontaneously adding food a different temperature to the bath after

reaching temperature) as well as varying water-food time constant (simulate

different volumes of foods, marinades in the food bag). Then show that for a

given set of gains there is little overshoot, and very stable performance.

For the most part, most gain choices will be stable enough,

but some will get the water to the desired temperature faster than others, and

in a commercial kitchen producing product on a time schedule that would mater. For

teaching your lap top how to make tuna confit, or perfect harcot verts, a

little simulation and some trial and error should be sufficient.

The key result from the simulation suggests using a PID with

a simple relay would work very well, and thus a rice cooker plugged into a

relay controlled by a PID should (in theory) be sufficient.

Phil is a Principal Software developer focusing on weird yet practical algorithms that run the gamut of embedded and desktop (PID loops, Kalman filters, FFTs, client-server SOAP bindings, ASIC design, communication protocols, game engines, robotics).

In his personal life he is a part time mad scientist, full time dad, and studies small circle jujitsu, plays guitar and piano.

General

General  News

News  Suggestion

Suggestion  Question

Question  Bug

Bug  Answer

Answer  Joke

Joke  Praise

Praise  Rant

Rant  Admin

Admin